Protective Relay Systems

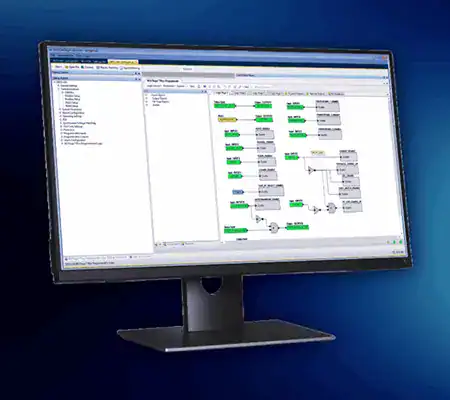

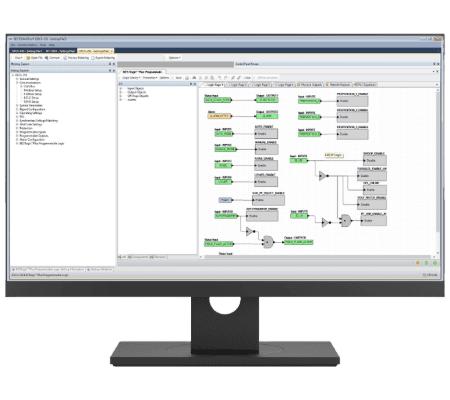

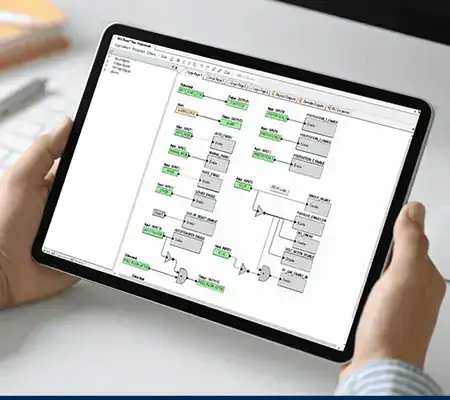

Reliable real-time protection and control for critical power systems. Ensure operational safety, minimize downtime, and maintain system integrity with our advanced protective relay systems.